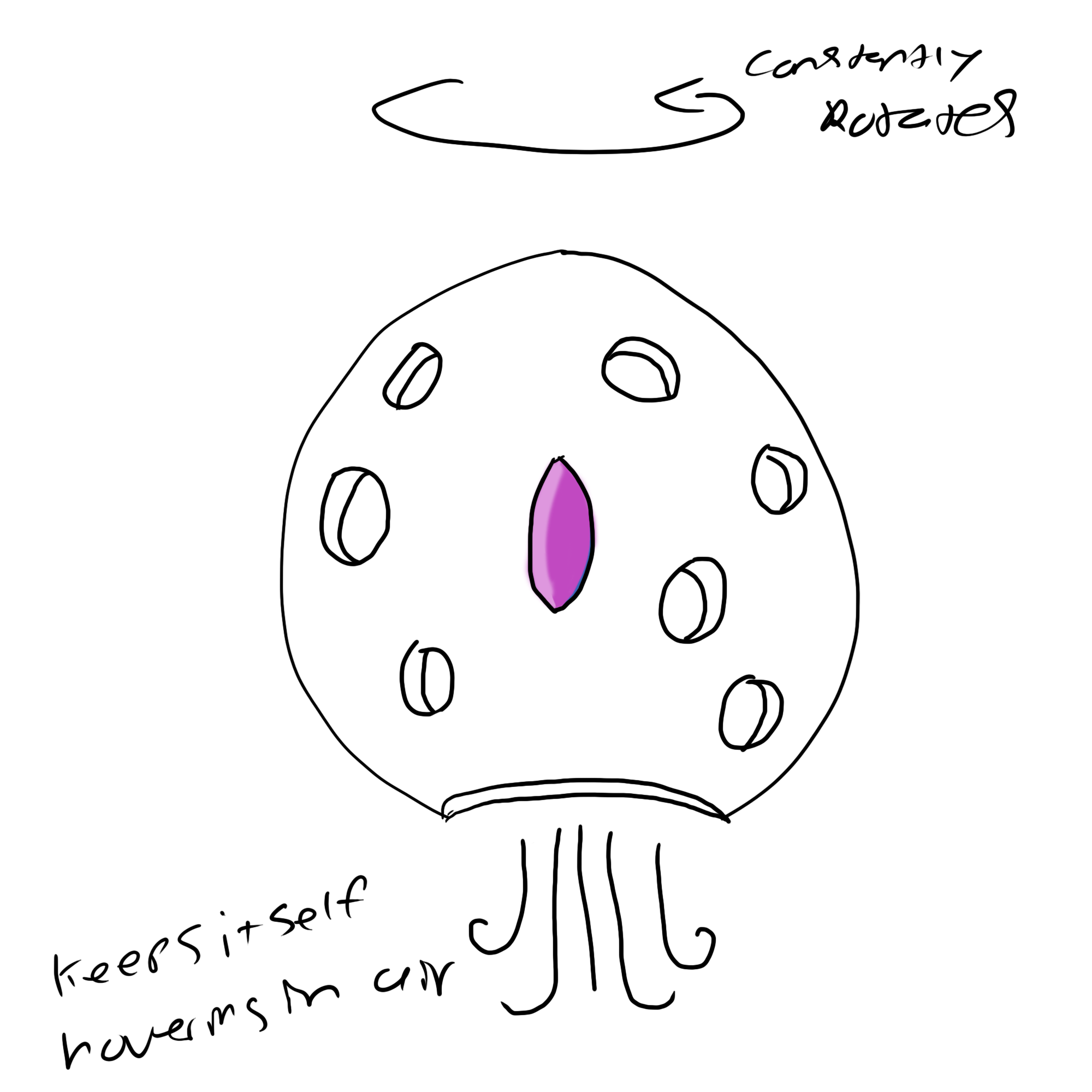

The hardest part about reaching our goal is the creation of these concentrated clouds. We have worked day in and day out to create these long lasting clouds following this guide. Our current solution to this problem is a new device we have created. Currently we call it project Skyward. We have created a mechanism that will keep our clouds everlasting. It’s design to control the temperature around it up to a radius of five miles. The device alone is able to hover in the air using strong turbines. Lastly it has a very powerful gravitational pull, using the valuable resource known as alomonium. It causes project Skyward to continuously spin in place, allowing itself to extrude enough gravitational force to maintain the shape of the clouds by keeping the water particles in the air very close together. This is how we have been able to create such dense clouds. The mixture of increasing the size of water particles, and condensing them in such small places allows for us to create a strong enough surface to be able to hold other solid structures on top of it. Currently, project Skyward seems to have a lifespan of about three years before needing a replacement. We will have to conduct a plan on how we are to go about replacing the devices when the time comes. Currently it seems safe enough to deploy the new device next to the old one to avoid any type of collapse with the cloud. We only hope this method continues to work as the devices become powerful in the future.

In order to obtain alomonium, we have decided to partner up with Pearl Mining Company. They have agreed to help us indefinitely and even in the future as we move to the skies. In preparation for that time, we have been working on a contraption to allow for travel in the air back down to the ground in a safely manner. The dangers we have with this travel is finding ways to keep the passengers safe during travel from the difference in air pressure, and what is the most efficient way to transport materials from the ground, up to thousands of feet in the air. We have been working on creating large vertical pipelines for transportation of materials. It is the quickest way to receive materials from the surface and does not require constant transportation of personnel to deliver. We will also be able to incorporate batching to help reduce the number of pipelines needed to make. When dealing with transportation of personnel, we have decided on making long shafts similar to elevators. We have incorporated many safety measures and pressure control in the elevator system. The elevator being made will have a current speed of traveling at 45mph. This will allow us to make sure our personnel don’t have to spend too much time traveling to the surface.